Tubing

When it comes to peristaltic tubing, the selection of the correct tube material is essential to enable your liquid to be transferred and to ensure maximum durability of the tubing.

In order to cover many different applications, a large selection of tube materials and sizes is available including custom-made tubing.

As far as high pressure hose pumps and industrial peristaltic pumps are concerned, we can offer you fabric-reinforced tubing made of NR, NBR, Hypalon and EPDM, for instance.

In order to eliminate any ambiguities regarding the relevant tube resistance it is recommended to carry out a 48-hour resistance test.

All other peristaltic pumps can also be used with the following tube materials:

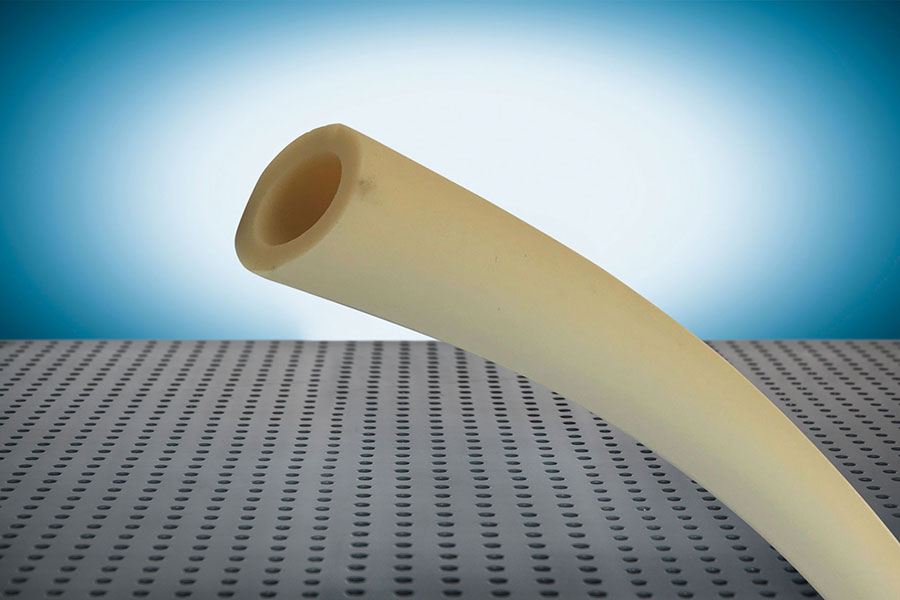

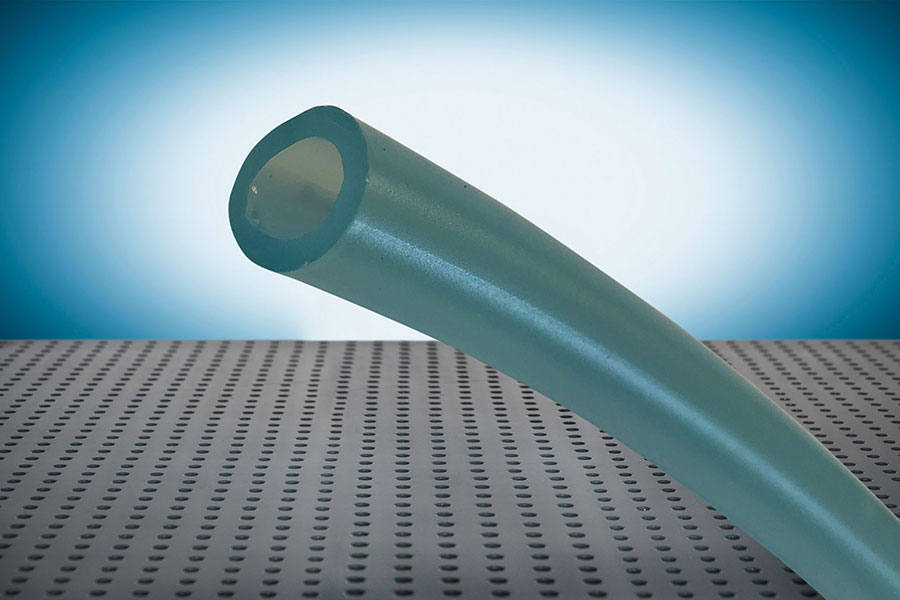

Lagoprene® Tubing for Peristaltic Pumps

A special manufacturing process and a 69-shore hardness ensure that unlike competitive products Lagoprene® tubing does not lose any of its recovery properties after a few hours of operation. Therefore there is no deviation from the pump’s performance within the first few hours. Lagoprene® has a beige colour and is ideal for the transference of aqueous solutions, mild acids and bases as well as alcohols.

| Properties | ASTM-Test | Lagoprene® |

|---|---|---|

| Density | ISO 1183 | 0.970 |

| Tensile Strength | D-412 | 450 |

| Ultimate Elongation (%) | D-412 | NK |

| Tensile Stress at 100% PSI | D-412 | NK |

| Durometer, Hardness, Shore | ISO 868 | 69 |

| Brittleness Temperature | D-746 | NK |

| Recommended Maximum Temperature | 100°C (212°F) | |

| Recommended Operating Temperature Range | -38,8°C bis +100°C (-38°F bis 212°F) | |

| Compression Set Test | D-395B | 18 |

| Yield Point in 100% | D-412 | NK |

NK= not known

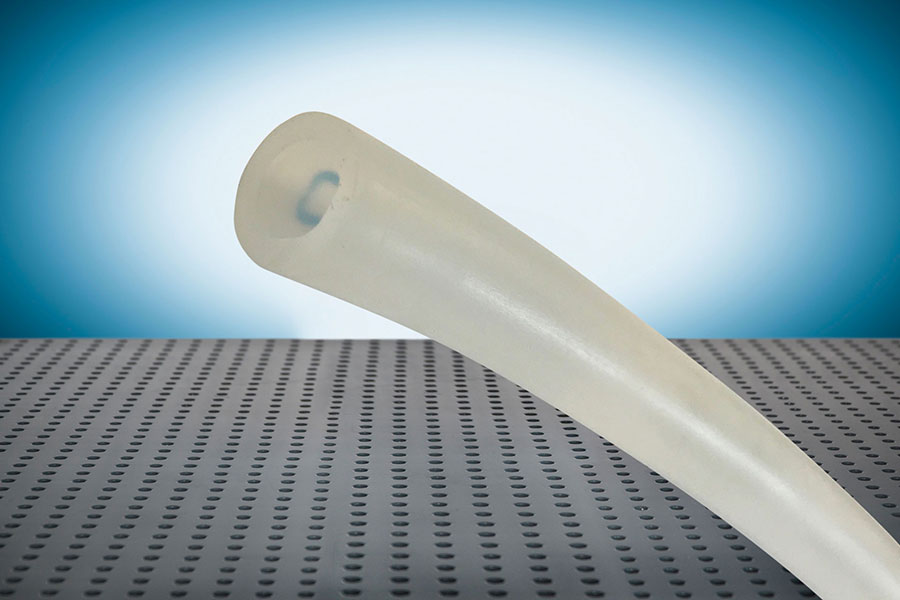

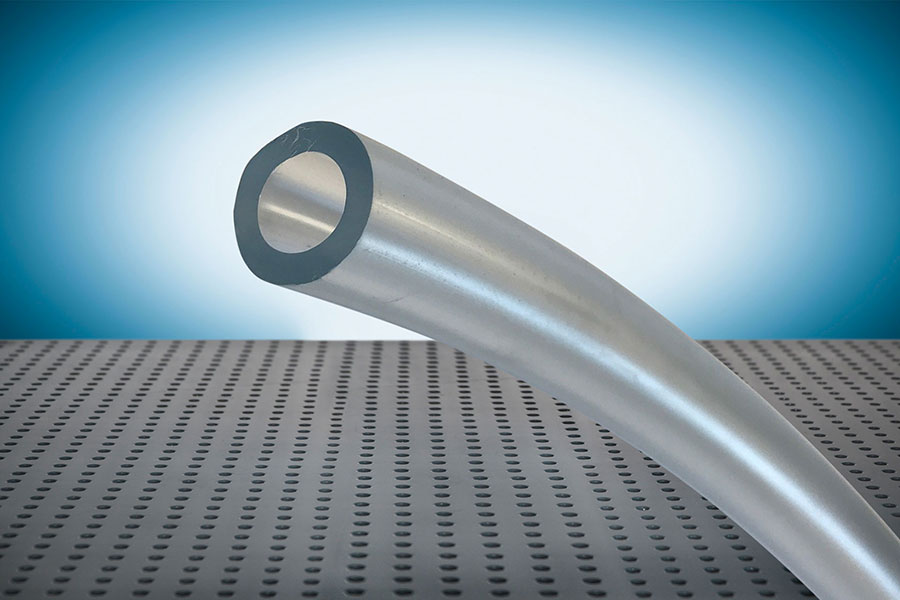

Cilran™ Tubing for Peristaltic Pumps

The chemical resistance of Cilran allows its use with acids, salts, alkalis and water based solutions and it is therefore ideal for peristaltic pump applications.

| Properties | ASTM-Test | Lagoprene® |

|---|---|---|

| Density | ISO 1183 | 0.970 |

| Tensile Strength | D-412 | 450 |

| Ultimate Elongation (%) | D-412 | NK |

| Tensile Stress at 100% PSI | D-412 | NK |

| Durometer, Hardness, Shore | ISO 868 | 69 |

| Brittleness Temperature | D-746 | NK |

| Recommended Maximum Temperature | 100°C (212°F) | |

| Recommended Operating Temperature Range | -38,8°C bis +100°C (-38°F bis 212°F) | |

| Compression Set Test | D-395B | 18 |

| Yield Point in 100% | D-412 | NK |

NK= not known

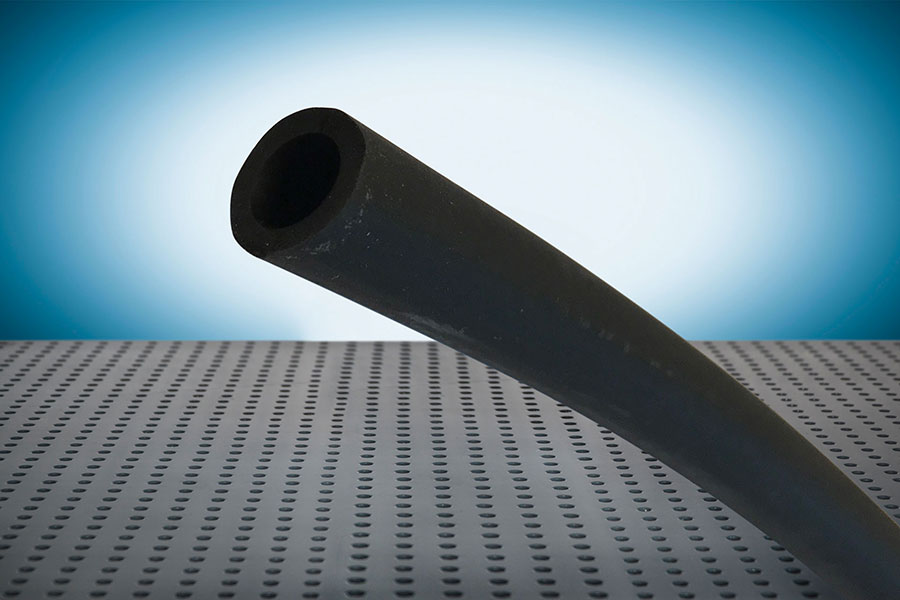

E-D Plex™ Tubing for Peristaltic Pumps

It can also be used for pumping certain oils and hydrocarbon based liquids.

E-D Plex™ combines the properties of EPDM and the chemical resistance of Neoprene™ and can therefore be used in a wide range of applications. It possesses elastomeric properties similar to vulcanized rubber and is ideal for peristaltic pumping applications due to its excellent flex fatigue properties.

| Properties | ASTM-Test | E-D Plex™ |

|---|---|---|

| Density | D-792 | 0.98 |

| Tensile Strength | D-412 | 928 |

| Ultimate Elongation (%) | D-412 | 374 |

| Tensile Stress at 100% PSI | D-412 | 386 |

| Durometer, Hardness, Shore | D-2240 | 65 |

| Brittleness Temperature | D-746 | -57°C (-71°F) |

| Recommended Maximum Temperature | 129°C (265°F) | |

| Recommended Operating Temperature Range | -40°C bis +87°C (-40°F bis +190°F) | |

| Compression Set Test | D-395B | 20 |

| Yield Point in 100% | D-412 | 11.9 |

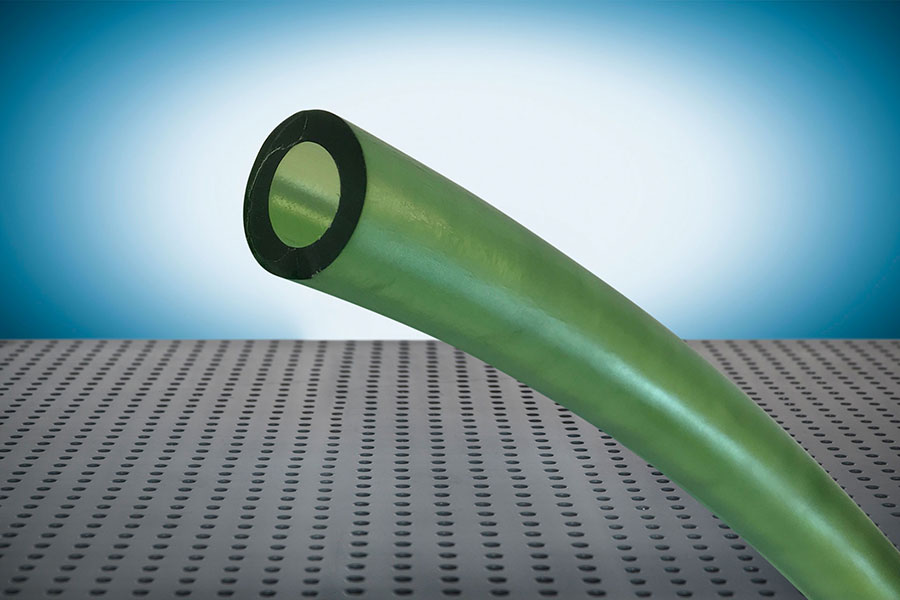

Povinal™ Tubing for Peristaltic Pumps

Povinal is a polyvinyl alcohol based tubing, ideal for pressures to 20 psi and temperatures of 15º to 125ºF (-9.4 º to 51 º C). It has the flexibility and strength for industrial settings where the handling of chemicals is a problem.

Povinal tubing has outstanding suitability for industrial applications. This can be attributed to the smooth inner wall which resists the formation of deposits, thus facilitating a free flow of liquid. Povinal is not suited for water or media containing large concentrations of water.

| Properties | ASTM-Test | Povinal™ |

|---|---|---|

| Density | D-792 | 0.90 |

| Tensile Strength PSI | D-412 | 1.440 |

| Ultimate Elongation (%) | D-412 | 450 |

| Tensile Stress at 100% PSI | D-412 | 325 |

| Durometer, Hardness, Shore | D-2240 | 60±5 |

| Brittleness Temperature | D-746 | NK |

| Recommended Maximum Temperature | 76°C (170°F) | |

| Recommended Operating Temperature Range | -9,4°C bis +51°C (-15°F bis +125°F) | |

| Compression Set Test | D-395B | NK |

| Yield Point in 100% | D-412 | 10,5 |

NK = not known

Prothane™ Tubing for Peristaltic Pumps

Due to its high flexibility it is a superior choice for peristaltic pump applications. Its good recovery properties improve the tube’s life. Apart from all its extraordinary qualities Prothane™ exhibits very good hydrolytic stability, good oil and fuel resistance and high tensile and tear strength.

It is resistant to diesel fuel, kerosene, motor oil, mild solvents, dilute acid and alkaline solutions and water and oil slurries.

Not recommended with ketones, brake fluid, aliphatic esters, chlorinated solvents, aromatic hydrocarbons, petrol, concentrated acid and alkaline solutions.

| Properties | ASTM-Test | Prothane™ |

|---|---|---|

| Density | D-792 | 1.18 |

| Tensile Strength PSI | D-412 | 3.154 |

| Ultimate Elongation (%) | D-412 | 870 |

| Tensile Stress at 100% PSI | D-412 | 380 |

| Durometer, Hardness, Shore | D-2240 | 70 |

| Brittleness Temperature | D-746 | - 68°C (-90°F) |

| Recommended Maximum Temperature | 104°C (220°F) | |

| Recommended Operating Temperature Range | -40°C bis +82°C (-40°F bis +180°F) | |

| Compression Set Test | D-395B | 19 |

| Yield Point in 100% | D-412 | 7,2 |

Vytex™ Tubing for Peristaltic Pumps

Strong acid solutions may be used with Vytex™ for short intervals, but should be flushed thoroughly with water after use.

The smooth surface allows for easy flushing and cleanup for food grade applications and beverage uses.

Vytex™ vinyl tubing is a durable, high flex tubing with a Shore “A” durometer of 60, allowing a long life expectancy for continuous flexing where peristaltic pumps are used.

This provides outstanding flow characteristics required in food grade tubing.

| Properties | ASTM-Test | Vytex™ |

|---|---|---|

| Density | D-792 | 1.18 |

| Tensile Strength PSI | D-412 | 1936 |

| Ultimate Elongation (%) | D-412 | 465 |

| Tensile Stress at 100% PSI | D-412 | 484 |

| Durometer, Hardness, Shore | D-2240 | 60 |

| Brittleness Temperature | D-746 | -53°C (-65°F) |

| Recommended Maximum Temperature | 82°C (180°F) | |

| Recommended Operating Temperature Range | -47°C bis 74°C (-54°F bis 165°F) | |

| Compression Set Test | D-395B | NK |

| Yield Point in 100% | D-412 | 9,7 |

NK = not known